Today, when consumers can always find the right product in an online store, it is more important than ever to monitor the availability of products in offline stores.Optimizing inventory managementwill definitely increase the efficiency of the chain, increase profits, and help avoid excessive or insufficient stock.

In recent years, modern technologies have significantly improved the capabilities of retailers. Artificial intelligence, machine learning, and in-depth analytics are used to achieve responsiveness, automate certain processes, and replace a large number of employees. All actions are taken to satisfy the consumer and make a profit.

In this context, retail replenishment becomes a critical operational and strategic discipline, directly affecting customer experience, supply chain stability, and financial performance across all sales channels.

What is Retail Replenishment?

Retail replenishment is the structured process of monitoring inventory levels across stores, warehouses, and sales channels, and restoring stock in the right quantity, at the right time, and in the right location.

Unlike simple reordering, modern retail replenishment connects demand forecasting, lead-time planning, supplier coordination, and allocation logic into a single replenishment system. Its goal is not just to refill shelves, but to support a seamless customer experience while optimizing inventory costs and availability across the entire supply chain.

Why do Retail Chains Need to Stock Up on Goods?

Stocking up on goods is a must for any retail chain to run smoothly. It keeps sales going, meets customer demand, and keeps the business financially stable.

The key reasons why retailers need to build and manage stock:

Ensuring sales continuity

Customer demand is constant, but deliveries often happen at specific intervals. Well-managed retail replenishment helps retailers avoid stockouts and empty shelves while goods are in transit or awaiting the next delivery.

In omnichannel retail, where online and offline demand must be fulfilled simultaneously, insufficient inventory in one channel can negatively impact the entire customer journey.

Offsetting logistics delays

Transportation always involves time — loading, shipping, unloading, and processing. Maintaining inventory allows retailers to bridge that gap and keep sales uninterrupted throughout the stock replenishment process.

Ignoring supplier lead times or upstream supply chain constraints often results in delayed fulfillment and lost sales opportunities.

Managing seasonal fluctuations in demand and supply

Many products are seasonal — from winter clothing to cold beverages. Retail replenishment enables retailers to prepare for peak sales periods when demand spikes but production or delivery capacity may be limited.

Advanced forecasting and optimization techniques allow retailers to sense demand changes early and avoid excess inventory after the season ends.

Balancing assortment between manufacturer and retailer

A manufacturer’s product range often doesn’t fully align with a retailer’s format or customer needs. Additional sorting, repackaging, or bundling is often required before items reach store shelves.

This makes accurate allocation of products across stores, regions, and channels a key component of effective retail replenishment.

Adapting to geographic supply constraints

When production sites or supplier warehouses are far away, retailers need to keep a safety stock to protect against logistical risks, delivery delays, or transport disruptions.

A centralized replenishment system helps calculate optimal buffer levels while minimizing capital tied up in inventory.

Meeting technical storage requirements

Certain product categories need special storage conditions — temperature control, humidity levels, and more. Controlled inventory levels ensure that these requirements are met, minimizing product spoilage or quality losses.

Improving purchasing efficiency

Buying in bulk is often more cost-effective than frequent small shipments. Retailers form stock reserves to lower logistics costs and negotiate better purchasing terms, making retail replenishment more economically efficient.

Stabilizing demand and profitability

Having sufficient stock on hand enables retailers to maintain consistent product availability even when production or deliveries fluctuate. This stability drives sales growth, customer loyalty, and overall profitability.

Therefore, inventory management is not just a warehouse operation, but a strategic tool for managing the stability, profitability, and competitiveness of a retail chain.

What is aStock Replenishment Strategy?

A retail replenishment strategy is a structured plan that defines how, when, and in what quantities inventory should be replenished to ensure the right products are available at the right time — without overstocking or running out.

In retail, it’s the backbone of smooth operations: an effective stock replenishment strategy keeps shelves full, customers satisfied, and working capital optimized.

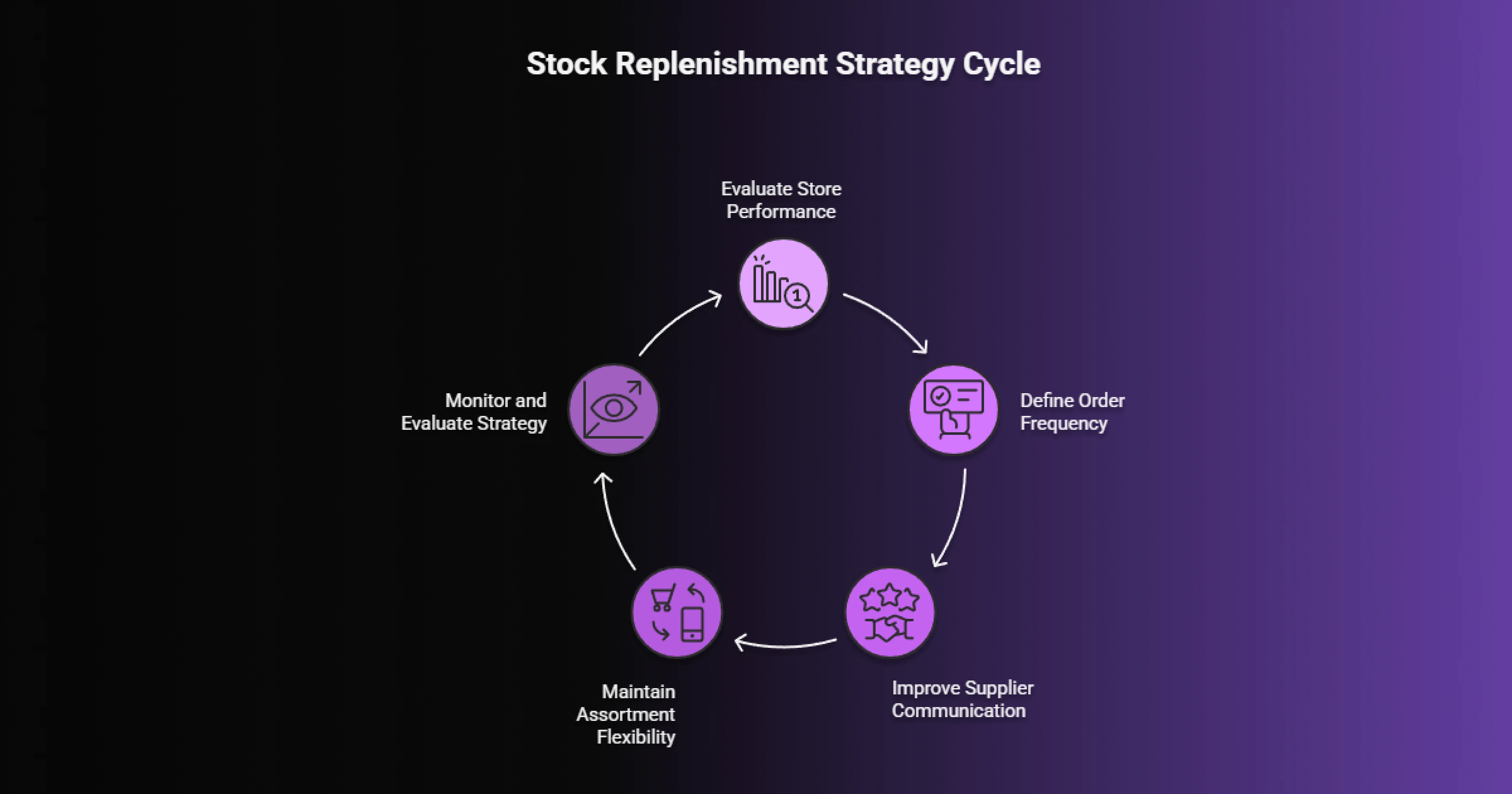

5 Key Stages of a Retail Replenishment Strategy

Evaluate store network performance

To build an effective replenishment strategy, start with a detailed analysis of past inventory reports. Historical data reveals seasonal trends, market dynamics, and consumer preferences.

Datawiz analytics goes further — it factors in promo-driven sales growth and identifies the top-performing assortment for each store location.

It’s also important to detect products with no recent sales to avoid unnecessary restocking in the next retail replenishment cycle.

Define order frequency and reorder points

Establish a reorder point — the level at which the system triggers a reminder or automatic order to restock.

Modern retail replenishment systems account for supplier lead times, delivery schedules, and safety stock requirements, ensuring inventory arrives before stockouts occur.

At the operational level, this is where the replenishment process is initiated.

Improve supplier communication

Replenishment success depends not only on finding suppliers but also on monitoring their performance. Delivery reliability, order accuracy, and fulfillment speed directly affect retail replenishment optimization.

Maintain assortment flexibility

Category managers should determine which SKUs can be replenished automatically and which require manual control due to seasonality or trend sensitivity.

Dynamic allocation rules help distribute inventory based on store format, regional demand, and sales velocity, reducing unnecessary stock replenishment.

Monitor and evaluate your replenishment strategy

To measure strategy effectiveness, track KPIs such as stockout rate, turnover ratio, inventory coverage, and service level.

Continuous monitoring allows retailers to refine retail replenishment optimization and respond quickly to market changes.

Effective Methods of Stock Replenishment

Effective Methods of Stock Replenishment

Time-based or Periodic Replenishment

Orders are placed at fixed time intervals, regardless of current inventory levels.

This method simplifies planning but requires careful demand forecasting to avoid excess stock replenishment.

Reorder Point or Continuous Replenishment

Inventory is replenished automatically once stock reaches a predefined minimum level.

This model is widely used in retail replenishment due to its responsiveness and scalability.

Forecast-based or Demand-driven Replenishment

Orders are generated using demand forecasts that factor in seasonality, promotions, and trends.

This method supports long-term optimization and reduces the risk of emergency stock replenishment or warehouse congestion.

FAQ: Retail Replenishment

How does replenishment support omnichannel retail?

It ensures visibility and availability of products across stores, warehouses, and online channels, reducing conflicts between demand sources.

Why is inventory distribution important?

Proper distribution determines where products are placed based on demand, store format, and sales velocity, directly affecting availability and profitability.

Can replenishment be automated?

Yes. Modern platforms automate forecasting, reorder points, supplier coordination, and reporting, significantly reducing manual effort.

Why is ongoing improvement essential?

Without continuous adjustments, retailers risk excess inventory, stockouts, or inefficient use of capital. Regular evaluation aligns demand, supply, and stock levels effectively.

Novedades

Novedades

¡No se necesita tarjeta bancaria!

¡No se necesita tarjeta bancaria!